The Original

Mag-Erad®

Patented Non-Toxic Scale Dissolver for glass-lined tank type bottom burner gas-fired residential water heaters Now also for: Tankless Water Heaters Electric Residential Tank Type Units

USE IN STANDARD BOTTOM BURNER GAS RESIDENTIAL

Now also for RESIDENTIAL TANKLESS UNITS

- SAVES ENERGY

- REDUCES NOISE

- RESTORES EFFICIENCY

The Problem

Hard water scale build up is a natural occurrence in all residential gas water heaters regardless of manufacture. As water heats, minerals precipitate out and form layers of sediment on the tank bottom. Pockets of water collect between these layers and create small steam explosions that cause rumbling, banging and popping noises. As the sediment build-up increases, these precipitates act as an insulating barrier between the water and the heat from the burner requiring much more energy to heat the water. This causes excess heat on the tank bottom which leads to premature tank failure.

The Solution

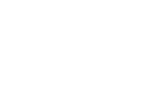

The answer to this universal problem is MAG-ERAD®, the patented FOOD GRADE chemical concentrate packaged in TWO POUND CANS. Mag-Erad contains NO DANGEROUS ACIDS OR POISONOUS CHEMICALS. Mag-Erad® is approved by leading water heater manufacturers for bottom burner type residential gas water heaters. Mag-Erad dissolves lime (calcium and magnesium carbonate) scale easily and safely. Simply shut down and drain the heater, follow the mixing directions on the label, pour the solution into the (side or top) relief valve opening, set the thermostat to 120°F and turn on the burner. Mag-Erad’s concentrated power is then released and changes the baked on solids into a liquid. Shut down heater, open the drain valve and flush out the liquid and follow Illustration A on Label. Follow the complete instructions on the label and consult heater manufacturer’s owner’s manuals. For Tankless Water Heaters Mix in a Ratio of 2 Pounds (One Can) per three gallons of warm (110°F.) water. Follow Original Equipment Manufacturers Instructions.

| AMOUNT OF MAG-ERAD® REQUIRED FOR RESIDENTIAL GAS WATER HEATERS | |

| HEATER SIZE(GALS) | MAG-ERAD(LBS) / (2 POUND) CANS |

| 30 THRU 40 | 2 Pounds /1 Cans |

| 50 THRU 75 | 4 Pounds / 2 Cans |

| 80 THRU 100 | 6 Pounds /3 Cans |

|

Amount of MAG-ERAD® Required for Tankless Residential |

|

NOTE: If pounding noise is severe, add an additional can of Mag-Erad® to the required amount, or repeat procedure as necessary

Available under Part No. 23602 in single lots. Also available in 6 Pack and 12 pack cartons. Mfg. by: Tri-Bros.™ Chemical Corp. 847-564-2320 www.tri-broschemical.com for more information

The following pages contain general instructions for removing carbonate lime scale from residential electric water heaters. A few tips: Plan to do the maintenance properly. Read the manufacturer’s installation manual and also pay particular attention to all the maintenance items to help enhance your and other’s safety. Generally, during the procedure, the element gaskets should be replaced with new gaskets, the sacrificial anode should be inspected and may require replacement, and the temperature and pressure relief valve will be removed for the entire procedure; new guidelines mandate it be removed and inspected at a minimum of every 2-4 years, and should there be any signs of deterioration or waterside blockage, or probe deterioration, it must be replaced with a CSA Rating of at least 100,000 BTU’s for a standard residential electric unit, and larger for high input units that exceed 29 kilowatts, a 205,000 BTU CSA to about 54 kilowatts which is equal to about 184,000 BTU. The NB Rating is for Pressure only and is not intended for potable system relief at the normal 20-80 pounds and keeping water under boiling in the event of a grounded element and any other potential runaway firing conditions. Never exceed the working pressure rating of the lowest rated component on the system. Where plastic pipe is used, check the pressure withstand since many plastics drop in pressure containment above 140 – 160°F, and at 210°F have virtually no containment ability. For that reason, a thermostatic mixing valve should be considered to help avoid an overheating tank from rupturing the plastic piping where the scalding water is then uncontained

USE IN STANDARD RESIDENTIAL ELECTRIC

(SINGLE OR DOUBLE ELEMENT) WATER HEATERS

- SAVES ENERGY

- REDUCES NOISE

- RESTORES EFFICIENCY

The Problem

Hard water scale build up is a natural occurrence in all residential electric water heaters regardless of manufacture. As water heats, minerals precipitate out and form layers of sediment on the heating elements, excess drops and fills the tank bottom. Pockets of water collect between these layers and create small steam explosions that cause heating element sizzling noises. As the sediment build-up increases, these precipitates act as an insulating barrier between the water and the heat from the elements causing the elements to overheat and either burn out if they are copper tin, or potentially become long rocklike tubes that can be difficult to remove if they are incolloy and take longer to burn out. The scale at the bottom can cause anodic areas and decrease cathodic protection from a working anode rod resulting in potential premature tank failure.

To use the Mag-Erad® to remove lime scale from residential electric water heaters, these general instructions are intended as a guide. Contact the manufacturer of the water heater for specific instructions that apply to their units.

You must be qualified to understand testing non-neutral (ex. energized 2 – 3 wire ungrounded conductors) 208 240 volt circuits. A test meter may seem to show zero, surface thermostats do not shut off the power, they open one leg, result is one side of the power is on, but an electrical meter will show zero volts if you test phase to phase. If you touch an energized wire, there will be an electric shock that can be life-threatening. Some water heaters are not properly grounded, especially when the conduit is non-metallic, and the ground wire is improperly installed. Also, many painted junction boxes do not conduct electricity, resulting in metallic conduit as a secondary ground to fail. Unrated connectors will not bite through the paint and make electrical contact with the water heater. Several scenarios such as plastic water pipe, or properly working di-electric unions will prevent a reading of the potential voltage present, from a contact electrical meter if you test terminal to ground using an isolated unit, where there is no effective ground. If you do not understand this material, take proper training as recognized in your governmental jurisdiction, and call a licensed electrician to work with you on the procedures. Also know that NFPA70E is a personal protective clothing and protective equipment code that must be understood and followed. Any arc flash can only be survived by luck, highly unlikely, or the proper protection. Beware of stories of people who tell you they regularly touch live wires. Those surviving people are few compared to those who are no longer with us. Follow safety procedures.

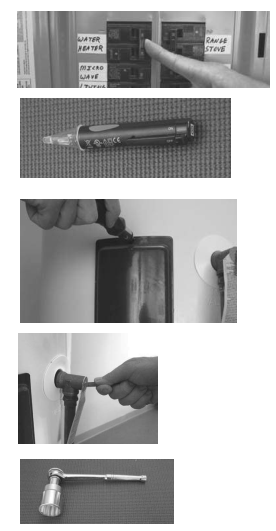

The very general procedure is to shut off all power to the electric water heater being delimed. Test that power is off. Lock out and tag the circuit(s). Remember, more than one circuit may supply any electrical unit. Carefully remove and store away from children about 10 gallons of hot water into clean buckets or other suitable containers that are easy to control for later use with the Mag-Erad, which will need 110 – 115° F Water. Run the hot water until cool water comes out of the faucets. This reduces the chances of a person being injured if water should have unintended contact during draining. Turn off the water supply to the unit. Because a pressurized expansion tank or water hammer arrestors can be on the line, it is important to open hot water faucets on a single valve unit, or if there is a cold shut off and a hot shut off on the unit, be sure to drain carefully, first slowly opening the drain assembly with the proper hose set up to a suitable floor drain, then when you are certain the pressure is relieved, carefully open the lever of the Temperature and pressure relief valve if it is properly piped to a floor drain to assure the pressure is relieved and then to allow air to enter the tank which will allow it to drain. Air-locking a tank is used by knowledgeable people when a drain valve is clogged and a different type of drain device is installed in its place. Do not attempt this if you are not properly trained. The water heater will drain down, and at that time, the temperature and pressure relief valve is removed from the tank.

After the Water Heater is Drained Down:

Remove the Electrical Panels that Cover the Heating Elements and Electric Thermostats

Disconnect the wires from the heating elements. Carefully move the wires away from the elements making certain not to break the wires or damage the insulation. Be careful not to loosen the wires from the thermostats since loose wires will overheat later and burn the thermostats.

Using 1-1/2” element wrench, or size recommended by manufacturer of the water heater, carefully unscrew the heating elements and slowly remove from the tank flange (spud). Sometimes lime scale is rather thick and some elements contain a loop. If the loop has spread apart, a screwdriver or other suitable tool may be used gently to use as a shoehorn, pulling the spread element end together which will allow the element to be carefully pulled out from the tank opening.

Using a brush or other tool, remove the excess lime scale from the heating element sheath. Also, use an ohm meter to test the element for the proper resistance. For example a 240 volt 4500 watt fixed resistance element is about 12.8 ohms, a 480 volt 6000 watt, 38.4 ohms, 240 volt 6000 watt, 9.6 ohms, 240 volt 3000 watt, 19.2 watt, 120 volt 2500 watt is 5.8 ohms. There should be an infinite reading from each element terminal to its flange plate.

Should the heating elements appear in good condition and test properly, and you do not want to replace them with new incolloy based elements, to remove the remaining scale from them, take 2 pounds of the Mag-Erad® and mix with three gallons of the 110 – 115°F water. In a container that will not allow the terminal block to contact the deliming solution, place the sheath of the element(s) in the Mag-Erad® solution. Leave in the solution until all foaming stops, then leave in another 15 to 30 minutes. Any remaining scale should be easily removed from the sheath with a gentle scraping unless it is silicate based scale. Any remaining scale over 1 16th inch can cause overheating of the element sheath which is especially important if the elements are comprised of copper and tin. Incolloy elements are much more burnout resistant.

Take a wet vac or other suitable method to remove the excess scale on the tank bottom through the opening of the removed lower element. Using the second 2 lb can of Mag-Erad®, mix with the 3 gallons the first 2 pound can was mixed in to make the element cleaning solution With a new gasket, replace the bottom heating element and tighten. Making sure the drain valve is turned off, using a funnel, slowly pour in the solution through the upper element opening being careful not to spill. Add one more gallon of the stored hot water. If it is an 80 gallon electric unit a third can of Mag-Erad should be used, especially depending on the scale that was unable to be removed via mechanical means. In the 80 or 120 gallon water heater there should be a total of the three cans mixed with about 8 gallons of water.

Special Notes: The Temperature and Pressure Relief Valve must be removed and physically inspected on the waterside every 2-4 years. If there is any deterioration of the probe or blockages of the waterside replace with a minimum 100,000 BTU CSA Rated Valve that is either 125 pound or 150 pound pressure rating as local code and the minimum component working pressure dictates. Next, if the unit has sacrificial anode rods, replace the anodes with the proper zinc aluminum or aluminum for non-chlorinated well water as recommended by the manufacturer or magnesium which is acceptable for low bacteria chlorinated water supplies and protects the tank due to higher current densities. Do not use an anode that is too short. It works by proximity. A big gap to the tank bottom means the bottom is not as protected. Consult the manufacturer if there are any questions. Be sure all threads and flanges are clean

Drain the solution from the tank and flush for at least 15 to 20 minutes, slowly, making sure the gate valve is slow enough to keep the water from filling the tank and overflowing the open upper element opening. After the time, shut the gate valve and make sure the tank is completely empty. Install the upper element, using a new gasket, connect the wires to the element(s) and check all wiring for correct tightness. Install a new or if in excellent condition, the existing Temperature and Pressure Relief Valve. Follow manufacturers installation instructions for filling and turning on your specific model of electric water heater and putting into service. Never use brushes or any tool that can create sparks to clean tank threads during deliming process. Follow all cautions on the Label of the Mag-Erad®